Consortium

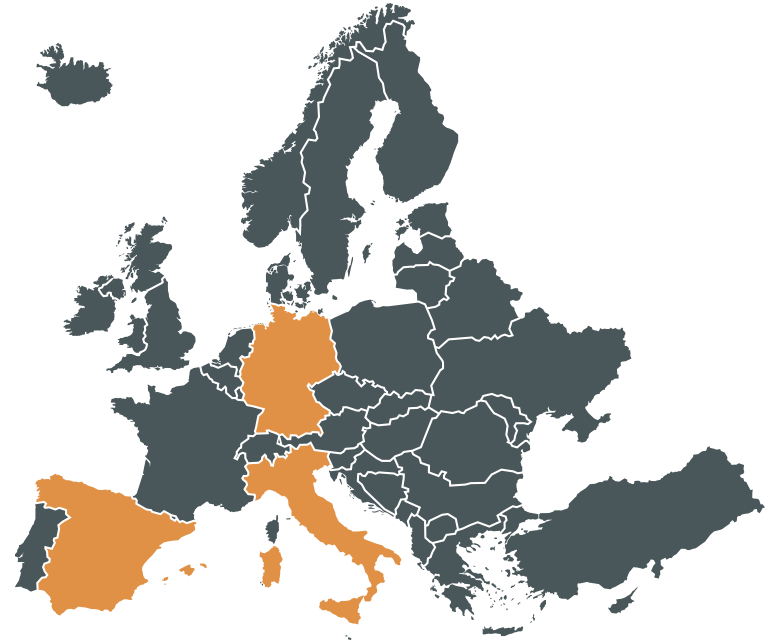

The AI-CUBE consortium is composed by 5 experienced partners coming from 3 different European countries and with proven capability to develop and achieve the aims of the project.

CiaoTech s.r.l / PNO Group B.V. PROJECT COORDINATOR

CIAOTECH s.r.l., a company 100% owned by the PNO Group B.V. (hereafter PNO), is the largest independent public funding and innovation consultancy in Europe, with 30 years of hands-on expertise with more than 600 innovation projects funded per year in most EU countries, annually raising approximately 1 Billion Euro for its clients. Created in 1985, PNO is a high-growth knowledge-intensive company, supporting over 2.000 clients throughout Europe, annually developing over 250 European consortia.

PNO has offices in 7 European countries and in Israel, employing in around 500 professionals including scientists, engineers, consultants, a Brussels policy advisory service, as well as financial and legal experts, with consolidated experience in innovation processes and funding in international working environments. The company specialized in Grants and Innovation Management, providing support services in Innovation processes, Technology Transfer, IT solutions and funding for research, development, and innovation. PNO “Innovation Management” services deliver high quality support to large companies, SMEs, Universities, Research Institutes, Associations, and clusters in the full cycle of the innovation process, including: • Analyzing, defining, and planning innovation processes • Building innovation networks, partnerships, and projects • Managing Projects and driving innovation

Zaragoza Logistics Center

Zaragoza Logistics Center (ZLC) is an international center of excellence for research and education in logistics and Supply Chain Management that actively engages with industry and the public sector to develop and disseminate knowledge to accomplish its mission. ZLC acts as a catalyst for innovation and research in the area of logistics and SCM. A core purpose of ZLC is to integrate supply chain management into the business enterprise.

ZLC was established by the Government of Aragon in Spain, in partnership with the MIT Center for Transportation and Logistics (CTL-MIT) and the University of Zaragoza. ZLC is directly linked to the development of PLAZA – the largest logistics park in Europe - and has partnered with the Center for Transportation and Logistics at MIT (CTL) to form the MIT-Zaragoza International Logistics Program. Also, the MIT Global SCALE (Supply Chain and Logistics Excellence) Network was initially formed in 2004, with the opening of ZLC, and it now spans four continents with the addition of the Center for Latin American Logistics Innovation (CLI-Colombia), the Malaysia Institute for Supply Chain Innovation (MISI), the Luxembourg Center of Logistics (LCL) and the Ningbo Supply Chain Innovation Institute China (NSIIC). In 2006 the Spanish Ministry of Education and Science designated ZLC as the National Centre of Excellence for research in the area of logistics and supply chain management (CNC-LOGISTICA). The research program is aligned to Zaragoza Logistics Center’s (ZLC) mission of focusing on enhancing economic growth and competitiveness through innovation. To this end ZLC has developed 150+ R&D collaborative projects with regional, national and European industry focused on logistics and SCM. At European level, ZLC has participated in 30+ European Union funded projects, being ranked as the Spanish entity with most EU funded projects in the field of logistics and SCM.

Fraunhofer Institute for Material Flow and Logistics (IML)

Fraunhofer IML was founded in 1981 in Dortmund, Germany, the IML currently occupies 315 employees as well as 250 post-graduates and students to works in all fields of internal and external logistics. In line with the Fraunhofer idea projects are followed in a twofold approach: Fraunhofer IML firstly develops problem solutions for direct use and implementation by companies, and secondly, conducts preliminary research of two to five years.

Teams form according to project and customer requirements to create cross-industry and customer-specific solutions in logistics, inter alia in the field of supply chain management & its simulation, closed loop economy and business process modelling. Artificial intelligence, smart finance and the Internet of Things are among the current research focal points. Fraunhofer IML coordinates the Internet of Things throughout Fraunhofer. With the current strategic focus on Silicon Economy, it explores new business models via platform economy approaches that centre on digitalisation and artificial intelligence. The key role from Fraunhofer IML within AI-CUBE lies within the expertise of AI and its use within supply chains and supply chain management. Fraunhofer IML supports the project twofold. Firstly, it provides strong experience in material stock management and supply chain for the process industry. Secondly, it supports on the use and application areas of AI within the field of supply chain management. With its expertise for AI and knowledge about the process industry, Fraunhofer IML guides the categorization of current AI and BD technologies. Being involved in the EU project “Transforming Transport”, Fraunhofer IML can refer to vast experience in the field of big data technologies in the area of transportation and create respective synergies. Its experience from the EU project “NextNet” supports methodologically for the evaluation of technologies used per sector and their level of maturity. Within the consortium Fraunhofer supports the exploitation of AI methods and BD technologies.

IRIS Technology Solutions S.L.

IRIS Technology Group (http://www.iristechnologygroup.com/) is an advanced engineering Group that was established in Barcelona in 2007. IRIS Technology Solutions S.L, located in Barcelona, specializes in the manufacture and integration of Process Analytical Technology (PAT)-based realtime quality monitoring solutions for the process industries and IoT systems for smart manufacturing, predominantly targeted at the food, pharmaceutical and chemical industries.

In particular, our product line comprises proprietary state-of-the-art IR analysers for at-line and in-line process monitoring. On the one hand, our solutions are based on the latest developments in photonics in the fields of MEMs, Near Infrared Spectroscopy, Hyperspectral Imaging, and Raman. On the other hand, we leverage ICTs, whereby we apply Machine learning, Artificial Intelligence and Data Mining techniques for predictive and active control, as well as for decision support systems. In addition to photonics-based analysers, we also work with IoT sensors for enabling equipment and machinery for smart manufacturing and transitioning industry to the Industry4.0 paradigm. Our solutions are cloudbased for mobility, remote monitoring and multi-site applications.

CNR-IEIIT

CNR-IEIIT is the Institute of Electronics, Computer and Telecommunication Engineering of the National Council of Research and carries out advanced research in the area of industrial and information engineering covering fields such as telecommunication, electronics, systems engineering and system modelling and networking achieving levels of national and international excellence.

These results are based on wide participation and experience gained participating to European, national, and regional projects. For what concerns research on Artificial Intelligence and Big Data, CNR-IEIIT is very active in several national and International initiatives with applications of System modelling &machine learning to robotics, food sector, manufacturing, bioengineering etc. CNR-IEIIT is involved in AI-CUBE for its experience in roadmapping and forecasting developed and will be involved in the activities related to the analysis and mapping of technologies and in particular into the definition of a assessment framework to evaluate the level of application of these technologies for the definition of a roadmap. The knowledge and background on Supply chain topics will be also used to developing project content in the macro-areas asked by the call.